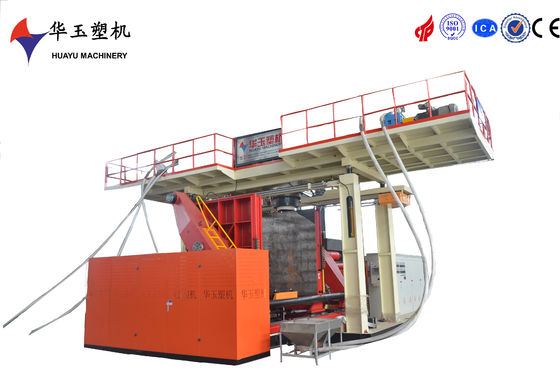

Triple Layer 2000L Water Tank Blow Moulding Machine HDPE

| Place of Origin | SHANDONG WEIFANG |

|---|---|

| Brand Name | HUAYU |

| Certification | CE,ISO9001 |

| Model Number | HY2000L-3Layer |

| Minimum Order Quantity | 1 SET |

| Price | Negotiate |

| Packaging Details | The machine will be disassembled into many parts for container transportation. |

| Delivery Time | 5 months |

| Payment Terms | L/C, T/T |

| Supply Ability | 4 sets per month |

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | HDPE | Control System | PlC |

|---|---|---|---|

| Main Operation Panel | Touch Screen 12'' | Servo Oil Pump Motor | 7.5kw |

| Servo Oil Pump Model | Plunger Pump22 | Servo Oil Tank Capacity | 200L |

| Main Oil Pump Motor | 57kw | Mian Oil Pump | Gear Pump160cc |

| Main Oil Tank Capacity | 1200L | Cooling Water Consumption | 60 Cubic Meters Per Hour |

| Highlight | 2000L Water Tank Blow Moulding Machine,Triple Layer Water Tank Blow Moulding Machine,HDPE blow moulding water tank |

||

Triple-Layer 2000L Blow Molding Machine for Enhanced Mechanical Strength

![]()

| Basic Specification | ||

| applicable material | HDPE |

China·HUAYU |

| capacity range | 500-2000L,3layers | |

| Voltage | Pending | |

| total power | 455kw | |

| average power | 310kw | |

| Machine dimension (L*W*H) | 8.5*6*7.2 | |

| productivity | 10-24pcs/h | |

| Auto Feeder | ||

| hopper material | stainless steel | Stable performance, easy maintenance |

| feeding type | spring loaded | |

| feeding motor | 2.2/2.2/2.2kw | |

| Extrusion System | ||

| Screw diameter | 110/130/110mm | Nitrided 38CrMoAIA |

| Screw L/D ratio | 28:1 | special designed screw can ensure the material plasticizing uniform and efficient |

| Extruder motor | 75/110/75kw | |

The Huayu 2000L three-layer blow molding machine is a cutting-edge industrial equipment designed for producing high-barrier, multi-functional 2000L containers (e.g., chemical tanks, food-grade storage drums).

Its triple-layer structure utilizes co-extrusion technology to combine distinct materials (e.g., outer UV-resistant layer, middle adhesive layer, inner anti-corrosion layer), enhancing mechanical strength, chemical resistance, and permeability prevention.

Equipped with a triple-head co-extrusion system and Siemens PLC + Moog servo control, it ensures precise material ratio adjustment (e.g., recycled core layer + virgin inner/outer layers) and automated thickness compensation.

The 120kg accumulator and dual-screw extruder enable a 25% faster cycle time compared to single-layer models, achieving daily outputs of 50-60 units. Certified by CE, FDA, and SGS, it meets stringent standards for food/pharmaceutical safety and hazardous material storage. Huayu provides customized solutions and 24/7 global technical support to optimize production efficiency.