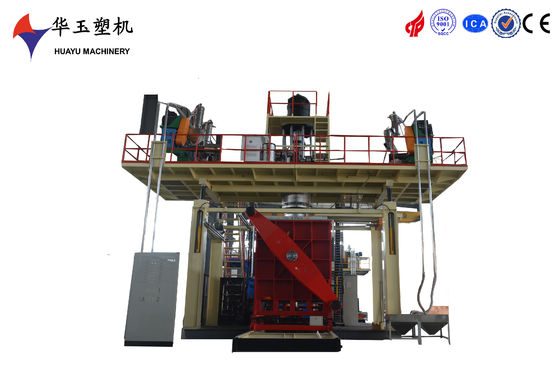

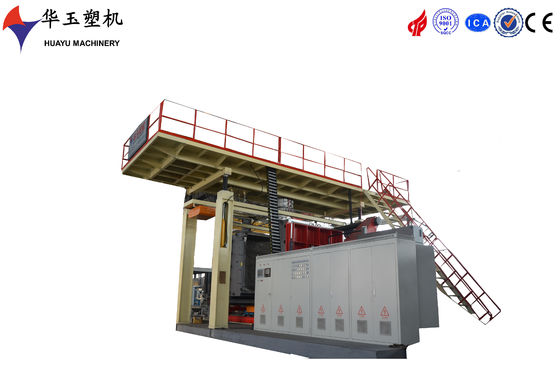

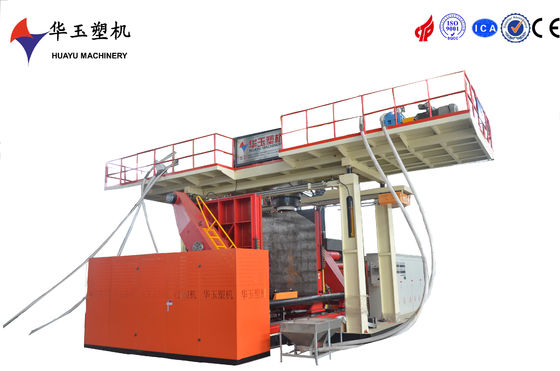

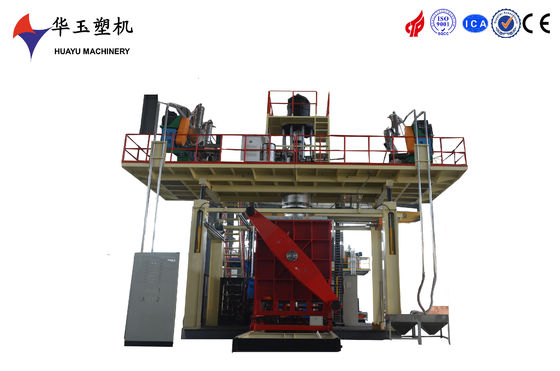

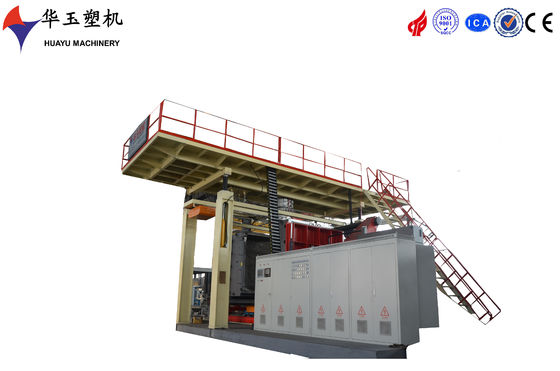

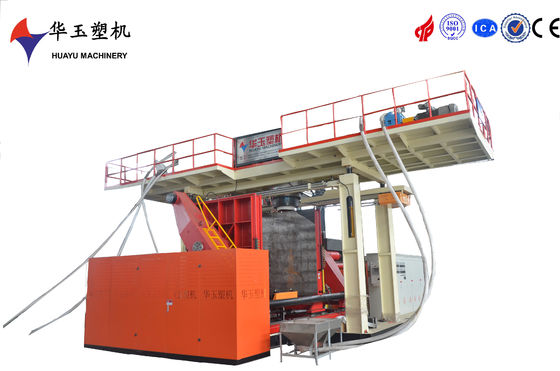

HUAYU 2000-2Blow Moulding Machine: High-Speed Production of Large Plastic Drums

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Machine Dimension | 5.5m*3.5m*4.5m | Touch Screen | Siemens |

|---|---|---|---|

| Key Selling Points | Long Service Life | Material | Plastic |

| Mould Material | Steel | Machine Demesion | 8.5*6*7.2 |

| Frequency | 50Hz/60Hz | Accumulator Capacity | 60kg |

| Hydraulic Oil Seal | DZ | Controller | PLC+Touch Screen |

| Reducer | 315/375/315 | Color | Customied |

| Cooling System | Water Cooling | Productivity | 10-24pcs/h |

| Air Consumption | 2.3m3/min | ||

| Highlight | huayu blow molding water tank,huayu water tank blow moulding machine,2000 blow molding water tank |

||

Introducing the HUAYU2000L-2 Blow Moulding Machine, engineered for efficiency in producing large plastic containers. This machine combines cutting-edge technology with a space-saving design, making it perfect for modern manufacturing facilities. Its high-speed production capability delivers exceptional output volumes, while the precision engineering ensures consistent product quality. The integration of energy-saving features reduces the carbon footprint, aligning with sustainable manufacturing practices. With minimal maintenance requirements and a durable build, it offers long-term reliability. Perfect for industries seeking to optimize their plastic production processes.

|

Auto Feeder |

||

|

hopper material |

stainless steel |

Stable performance, easy maintenance |

|

feeding type |

spring loaded |

|

|

feeding motor |

1.5/1.5kw |

|

|

Extrusion System |

||

|

Screw diameter |

120/120mm |

Nitrided 38CrMoAIA |

|

Screw L/D ratio |

28:1 |

special designed screw can ensure the material plasticizing uniform and efficient |

|

Extruder motor |

90/90kw |

|

|

Reducer |

330/330 |

Best quality brand in china ,long life and low noise |

|

Screw heating power |

5.5kw*12 |

|

|

Plasticizing capacity |

600kg/h |

|

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()