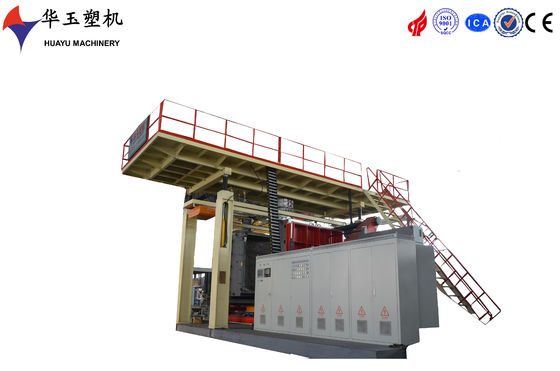

Stainless Steel 5000L 6-Layer Hollow Blow Molding Machine High-Efficiency for Water Tanks Industrial Containers

| Place of Origin | SHANDONG WEIFANG |

|---|---|

| Brand Name | HUAYU |

| Certification | CE,ISO9001 |

| Model Number | HY5000L-6 Layers blow moulding machine |

| Minimum Order Quantity | 1 SET |

| Price | Negotiate |

| Packaging Details | The machine will be disassembled into many parts for container transportation. |

| Delivery Time | 4 months |

| Payment Terms | L/C, T/T |

| Supply Ability | 4 sets per month |

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Total Power | 690kw | Average Power | 440kw |

|---|---|---|---|

| Machine Dimension | 13*11*9.4 | Machine Weight | 92T |

| Die Head Weight | 26T | Productivity | 4-18pcs/h |

| Hopper Material | Stainless Steel | Feeding Type | Spring Loaded |

| Feeding Motor | 2.2kw*6 | Screw Diameter | 100mm*6 |

| Screw L/D Ratio | 28:1 | Extruder Motor | 5.5kw*6 |

| Reducer | 280*6 | Screw Heating Power | 5.5kw*16 |

| Highlight | 6-Layer Hollow Blow Molding Machine,Stainless Steel Hollow Blow Molding Machine,High-Efficiency Hollow Blow Molding Machine |

||

5000L 6 layers blow moulding machine, mainly used for produce water storage tanks, capacity range 1000~5000L. Otherwise can be designed for producing non-standard products according to customer’s request.

Servo motor ,

IKV screw barrel ,

Diehead seals use hard seal

Moog 200 points

Touch screen 12’’

New type of robot arm

Made in China & Made by Weifang Huayu Plastic Machinery Co.,Ltd.

The seller transports the goods to Qingdao Port, China after inspection of machine.

All the inspection work should be performed as the technical configurations and parameters which are stipulated in the contract.

The machine will be disassembled into many parts for container transportation. The seller is responsible for packing and fixing all these parts in container well according to their own experience.

The seller’s machine should be passed the ISO9001, CE certification.

| 基本参数 Basic Specification | ||

| 适用原料applicable material | HDPE | 中国·华玉 China·HUAYU |

| 产品容量范围capacity range | 1000-5000L,6layers | |

| 电压Voltage | Pending | |

| 总功率total power | 690kw | |

| 平均功率average power | 440kw | |

| 机器尺寸Machine dimension (L*W*H) | 13*11*9.4 | |

| 机器重量Machine weight | 92T | |

| 机头重量Die head weight | 26T | |

| 产品产量productivity | 4-18pcs/h | |

| 自动上料Auto Feeder | ||

| 料斗材料hopper material | 不锈钢stainless steel | Stable performance, easy maintenance |

| 上料形式feeding type | 弹簧上料spring loaded | |

| 上料电机feeding motor | 2.2kw*6 | |

| 挤出系统 Extrusion System | ||

| 螺杆直径Screw diameter | 100mm*6 | Nitrided 38CrMoAIA |

| 螺杆长径比Screw L/D ratio | 28:1 | special designed screw can ensure the material plasticizing uniform and efficient |

| 挤出电机Extruder motor | 55kw*6 | |

| 减速机Reducer | 280*6 | Best quality brand in china ,long life and low noise |

| 螺杆加热功率Screw heating power | 5.5kw*16 | |

| 塑化能力Plasticizing capacity | 1000kg/h | |

| 机头 die head | ||

| 料缸容量Accumulator capacity | 150kg | designed by ourselves and get the patent |

| 口模直径Die diameter | According to products | |

| 机头加热功率Die head heating power | 170kw | |

| 合模系统 Clamping System | ||

| 模板尺寸platen size | 2400*2500*70mm(W*H*T) | smooth running, no noise; the clamping force is big |

| 合模油缸clamping cylinder | 350*1+200*2 | |

| 合模油缸行程clamping cylinder stroke | 2200mm | |

| 锁模力clamping force | 3000KN | |

| 模板间距distance between platens | 1600-4000mm | |

| 最大模具尺寸max. mould size | 1800*2500mm(W*H) | |

| 吹气和冷却系统 blowing and cooling system | ||

| 扩展行程stretching stroke | according to products | |

| 吹针上下行程blow pin up/down stroke | 600mm | |

| 气座升降行程air seat stroke | 400mm | |

| 最大气压maximum air pressure | 0.8Mpa | |

| 耗气量air consumption | 3m3/min | |

| 冷却方式Cooling method | Circulating water | |

| 冷却水压Water pressure | 0.3MPa | |

| 冷却水量Cooling water consumption | 5m3/h | |

| 液压系统 Hydraulic system | ||

| 主油箱容量main oil tank capacity | 1700L | Servo motor, less energy consumption, high efficiency, low noise |

| 主油泵main oil pump | gear pump185CC | |

| 主油泵电机main oil pump motor | 75kw | |

| 伺服油箱Servo oil tank capacity | 200L | |

| 伺服油泵Servo oil pump model | Plunger pump22 | |

| 伺服油泵电机Servo oil pump motor | 7.5kw | |

| 电气系统Electronic system | ||

| 主要操作面板Main operation panel | Touch screen 12" | |

| 控制系统Control system | PLC | |

| 壁厚控制点数Thickness control points | 200 points | |

| 温度控制Temperature control | PLC module | |

| 主体框架main frame | ||

| Up/down stroke | 500mm | |

| Up/down motor | 4kw | |

![]()

![]()

![]()

![]()

![]()