Small HDPE Plastic Blow Molding Machine For Medical Floor Bed

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Brand Name | Huayu | Material | HDPE |

|---|---|---|---|

| After-sales Service Provided | Service Machinery Overseas | Warranty | 12months |

| Product Name | Automatic Blowing Molding Machine | Clamping Force (kN) | 800 |

| Output (kg/h) | 450 | Core Components | PLC, Engine, Bearing, Gearbox, Motor, Pressure Vessel, Gear, Pump |

| Place Of Origin | Shandong, China | ||

| Highlight | HDPE plastic blow moulding machine,Small plastic blow moulding machine,450kg/h hdpe moulding machine |

||

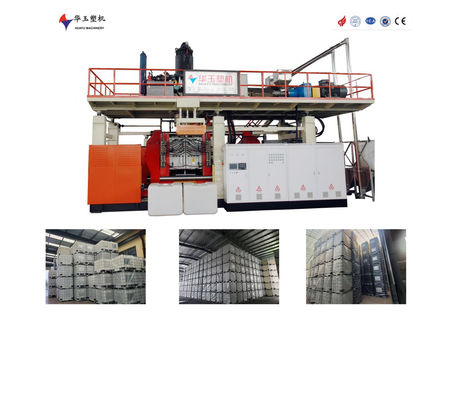

HUAYU Long-Lasting Medical Floor Bed Blow Molding Machine with Tailor-Made Options

Would it be beneficial if you could provide us with detailed product drawings? This would enable our engineers to devise the most suitable technical proposal and pricing for you. We strongly encourage the submission of detailed product drawings. These drawings provide our engineers with a comprehensive understanding of your product specifications, enabling them to develop a tailor-made technical proposal. By having a clear visualization of your requirements, we can meticulously design and engineer a solution that maximizes efficiency, quality, and cost-effectiveness. The resulting proposal and pricing will be precisely aligned with your unique needs, ensuring a seamless integration into your existing operations.

PRODUCT DETAILS

![]()

![]()

![]()

![]()