2000-2 Blow Moulding Machine User-Friendly Interface for Large-Scale Plastic Production

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Range | 1000L IBC TANK | Machine Dimension | 12*7*7m |

|---|---|---|---|

| Machine Type | High Speed Plastic Bottle Making Machine | Layers | 2 LAYERS |

| Output | 450KG/H | Extruder Motor Power | 75kw |

| Average Power Consumption | 300kw | Durability | Excellent |

| After Sales | OVERSEAS SERVICE | Color | Customizable |

| Weight | 69Ton | Extrudor Motor | 110/90*2/15*3 |

| Extruder Diameter | 90mm | Mold Stroke | 1000mm |

| Control System | PLC Control | ||

| Highlight | Large-Scale Blow Moulding Machine,User-Friendly Interface Blow Moulding Machine |

||

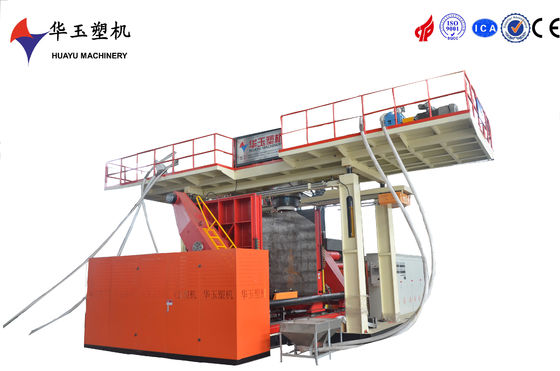

The HUAYU2000L-2 Blow Moulding Machine is designed with a user-friendly interface, making it easy to operate and monitor. It features advanced automation and precision engineering, ensuring high precision and consistent product quality. With a maximum container size of 1800L, it offers a production capacity of 1100-1600 units per hour, powered by a 65KW motor. Its dimensions are 7500mm x 3000mm x 3500mm. This machine is ideal for manufacturing large plastic containers, drums, and industrial plastic products, with wide applications in chemical, agricultural, and logistics sectors. The user-friendly interface simplifies operation and monitoring, while the high-speed production delivers exceptional output volumes with minimal cycle times. The precision engineering ensures consistent product quality and dimensional stability, and the durable construction with robust frame and precision components ensures a long service life. It includes automated calibration for precise mold alignment, real-time monitoring for tracking production parameters, and quick changeover for different product sizes and shapes. Detailed operating instructions and maintenance guidelines are provided, and regular maintenance is necessary. It should be operated within specified temperature and pressure ranges, following safety protocols. Shipment is carefully coordinated with reliable logistics partners, and flexible payment options are available. The machine is securely packaged to prevent transit damage, with customized packaging solutions upon request. A 12-month warranty is provided, with customer service support for any purchase-related issues.

|

Hydraulic system |

||

|

main oil tank capacity |

1200L |

Servo motor, less energy consumption, high efficiency, low noise |

|

main oil pump |

gear pump160CC |

|

|

main oil pump motor |

45kw |

|

|

Servo oil tank capacity |

200L |

|

|

Servo oil pump model |

Plunger pump22 |

|

|

Servo oil pump motor |

7.5kw |

|

![]()