All Products

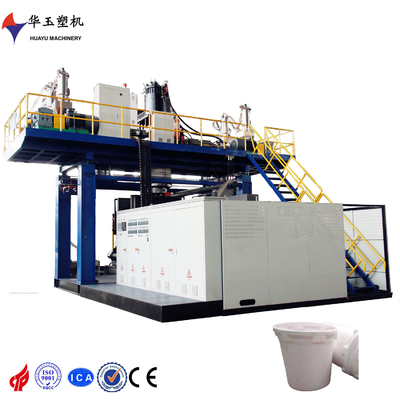

1200L 3-Layer HDPE Blow Moulding Machine for Agricultural Containers

Product Details

| Blow Molding Type | Single Station | Key Selling Points | Long Service Life |

|---|---|---|---|

| Extruder Motor Power | 110kW | Color | Customized |

| Layer | 3 Layers | Mould Material | Aluminum |

| Cooling System | Water Cooling | Power Supply | 380V/50Hz |

| Product Material | HDPE | Heating Power | 40kW |

| Extrudor Motor | 55kw*6 | Productivity | 10-24pcs/h |

| Mold Type | Single Station | Feeder Type | Vacuum Feeder |

| Recyclability | Recyclable | ||

| Highlight | 1200L HDPE blow moulding machine,3-layer agricultural container machine,water tank blow moulding equipment |

||

You can tick the products you need and communicate with us in the message board.

Product Description

Blow Moulding Machine: Agricultural 3-Layer 1200L Plastic Container Production

Product Specifications

| Attribute | Value |

|---|---|

| Blow Molding Type | Single Station |

| Key Selling Points | Long Service Life |

| Extruder Motor Power | 110kW |

| Color | Customized |

| Layer | 3 Layers |

| Mould Material | Aluminum |

| Cooling System | Water Cooling |

| Power Supply | 380V/50Hz |

| Product Material | HDPE |

| Heating Power | 40kW |

| Extrudor Motor | 55kw*6 |

| Productivity | 10-24pcs/h |

| Mold Type | Single Station |

| Feeder Type | Vacuum Feeder |

| Recyclability | Recyclable |

Product Description

The HUAYU1200L-3L Blow Moulding Machine is engineered for agricultural applications, featuring advanced automation and energy-efficient technology. This machine delivers high precision and low operational costs, making it ideal for producing 3-layer 1200L plastic containers and drums for agricultural use.

Die Head Specifications

| Accumulator capacity | 60kg |

| Die diameter | According to products |

| Die head heating power | 100kw |

Designed by ourselves and patented

Clamping System Specifications

| Platen size | 1900*2000*60mm(W*H*T) |

| Clamping cylinder | 200+280*2 |

| Clamping cylinder stroke | 2000mm |

| Clamping force | 1800KN |

| Distance between platens | 1000-3000mm |

| Max. mould size | 1600*2000mm(W*H) |

Smooth running, no noise; the clamping force is big

Recommended Products