All Products

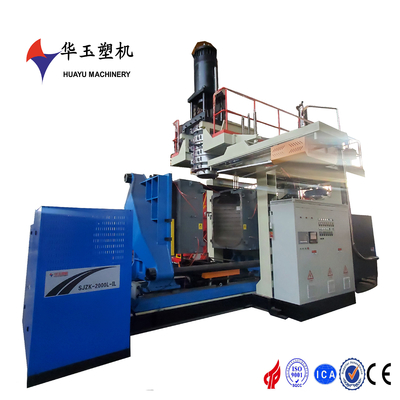

HUAYU 2100L Blow Moulding Machine for Plastic Water Tanks

Product Details

| Key Selling Points | Long Service Life | Attribute | Drawings Customize |

|---|---|---|---|

| Parison Control | MOOG 200point | Displacement Pickup | Jefran |

| Condition | New | Extruder Motor | 5.5kw*6 |

| Clamping Cylinder | 350+200*2 | Platen Distance | 2300-5500MM |

| Layers | 1 LAYER | Cooling Water Pressure | 0.3-0.6MPa |

| Material | Plastic | Plc | Siemens |

| Air Consumption | 1.2 M3/min | Cooling Method | Circulating Water |

| Screw Dia | 150mmx1 | ||

| Highlight | HUAYU 2100L plastic water tank machine,blow moulding machine for water tanks,industrial water tank blow moulder |

||

You can tick the products you need and communicate with us in the message board.

Product Description

HUAYU Blow Moulding Machine - Smart 10-Layer 2100L Plastic Container Production

Key Specifications

| Attribute | Value |

|---|---|

| Key Selling Points | Long Service Life |

| Attribute | Drawings customize |

| Parison Control | MOOG 200point |

| Displacement Pickup | Jefran |

| Condition | New |

| Extruder Motor | 5.5kw*6 |

| Clamping Cylinder | 350+200*2 |

| Platen Distance | 2300-5500MM |

| Layers | 1 LAYER |

| Cooling Water Pressure | 0.3-0.6MPa |

| Material | Plastic |

| PLC | Siemens |

| Air Consumption | 1.2 m3/min |

| Cooling Method | Circulating water |

| Screw Dia | 150mmx1 |

Product Description

The HUAYU2100L-10L Blow Moulding Machine integrates smart technology, making it ideal for 10-layer 2100L plastic container production. It ensures high precision and consistent product quality, with features like automated calibration and real-time monitoring enhancing productivity.

Auto Feeder

Hopper material: stainless steel - Stable performance, easy maintenance

Ding type: spring loaded

Feeding motor: 2.2/2.2/2.2/2.2kw

Extrusion System

Screw diameter: 110/110/110/110mm - Nitrided 38CrMoAIA

Screw L/D ratio: 28:1 - Special designed screw can ensure the material plasticizing uniform and efficient

Extruder motor: 75/75/75/75kw

Reducer: 315/315/315/315 - Best quality brand in China, long life and low noise

Screw heating power: 4.4kw*16

Plasticizing capacity: 800kg/h

Recommended Products