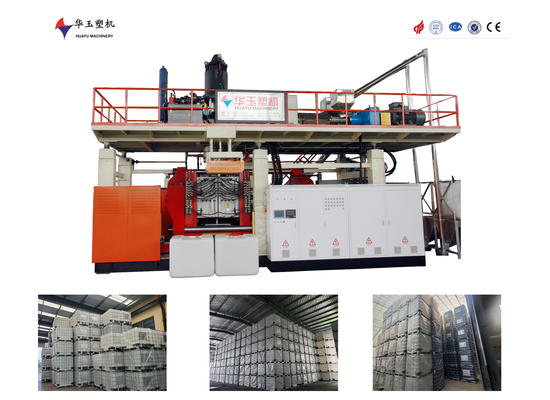

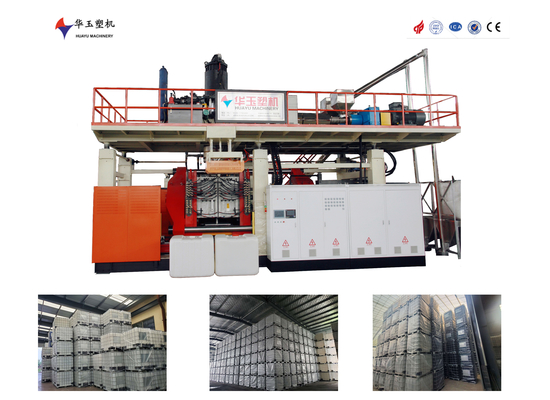

1000L 2-Layer Large Heavy-Duty Water Tank Blow Molding Machine

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Size | Customized | Screw Barrel Material | 38CrMoAlA,Nitriding |

|---|---|---|---|

| Cleaning Method | Easy Cleaning | Range | 1000L IBC TANK |

| Layers | 5 Layers | Screw Heating Power | 5.5kw*12 |

| Platen Distance | 1100-2500MM | Voltage | 220V/380V |

| Year | 2024 | Motor | Siemens |

| Machine Dimension | 12*11*7.5M | Mian Oil Pump | Gear Pump160cc |

| Product Range | 1000L | Plc | Siemens |

| Color | Customied | ||

| Highlight | 1000L water tank blow molding machine,heavy-duty water tank molding machine,2-layer water tank blow moulder |

||

This 1000L two-layer heavy-duty blow molding machine is designed for producing high-quality multi-layer plastic products. The dual-layer co-extrusion system allows for enhanced material flexibility and improved product performance. The heavy-duty water tank cooling system ensures efficient heat dissipation and maintains optimal operating temperatures, enhancing production efficiency. The machine's advanced control system offers precise control over the molding process, ensuring consistent product quality. Its durable design and reliable performance make it suitable for industries requiring large, multi-layer plastic products. The water tank system is designed for easy maintenance and long-term reliability, making this machine a cost-effective and efficient solution for your production needs.

|

Clamping System |

||

|

platen size |

1700*1800*70(W*H*T) |

smooth running, no noise; the clamping force is big |

|

clamping cylinder |

300 |

|

|

clamping cylinder stroke |

1800mm |

|

|

ng force |

1000KN |

|

|

distance between platens |

900-2700mm |

|

|

max. mould size |

1500*1700mm(W*H) |

|

|

blowing and cooling system |

||

|

ing stroke |

according to products |

|

|

blow pin up/down stroke |

600mm |

|

|

ir seat stroke |

400mm |

|

|

maximum air pressure |

0.8Mpa |

|

|

air consumption |

1.5m3/min |

|

|

Cooling method |

Circulating water |

|

|

Water pressure |

0.3MPa |

|

|

Cooling water consumption |

3m3/h |

|

![]()