Electric Kayak Molding Machine Customized Frequency 60Hz Robust Solution Designed for Kayak Production and Manufacturing

| Control System | PLC | Capacity | Plastic Kayak/boat |

|---|---|---|---|

| Model | HYBM-kayak | Molding Method | Blow Moulding |

| Power Source | Electric | Key Selling Points | Easy To Operate |

| Frequency | 60Hz | Color | Customied |

| Highlight | Electric kayak molding machine 60Hz,Customized kayak molding machine,Robust kayak production machine |

||

Product Description:

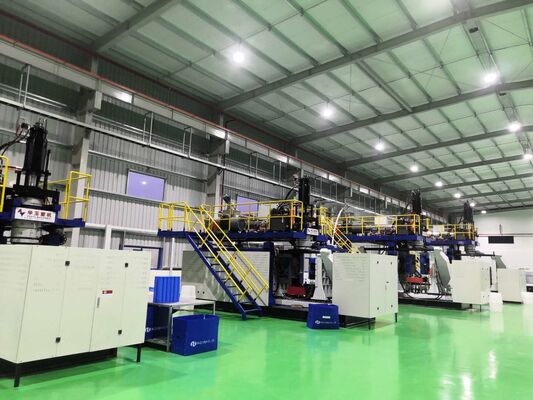

The HYBM-kayak is a state-of-the-art kayak blow moulding machine designed specifically for the efficient and high-quality production of plastic kayaks and boats. Engineered with precision and user convenience in mind, this plastic kayak making machine offers an ideal solution for manufacturers seeking to optimize their production processes while maintaining superior product standards. Equipped with a robust 70kg accumulator, the HYBM-kayak ensures consistent material supply and smooth operation, which is crucial for producing durable and reliable plastic kayaks.

One of the standout features of the HYBM-kayak kayak blow moulding machine is its ease of operation. The machine is designed to be user-friendly, allowing operators to quickly learn and manage the production line without extensive technical training. This ease of operation significantly reduces downtime and increases overall productivity, making it an excellent choice for both small-scale and large-scale kayak manufacturers. The intuitive interface and streamlined workflow contribute to a seamless manufacturing experience, ensuring that every plastic kayak produced meets stringent quality requirements.

At the heart of the HYBM-kayak plastic kayak making machine is an advanced PLC (Programmable Logic Controller) control system. This sophisticated technology provides precise control over all aspects of the blow moulding process, from temperature regulation to cycle timing and material injection. The PLC system enhances the machine’s reliability and accuracy, resulting in consistent product quality and reduced waste. Additionally, the control system allows for easy customization and adjustment of production parameters, enabling manufacturers to adapt quickly to different kayak designs and material specifications.

Capacity is a critical factor in any manufacturing equipment, and the HYBM-kayak excels in this area. With its 70kg accumulator capacity, this plastic kayak making machine can handle substantial volumes of raw material, facilitating continuous production without frequent interruptions. This high capacity supports the manufacturing of various sizes and types of plastic kayaks and boats, catering to diverse market demands. Whether producing recreational kayaks or specialized boats, the HYBM-kayak ensures efficient material utilization and optimal throughput.

Durability and reliability are paramount in the kayak blow moulding machine industry, and the HYBM-kayak meets these requirements with exceptional build quality and engineering excellence. The machine’s robust construction minimizes maintenance needs and extends operational lifespan, providing excellent return on investment for manufacturers. Its design also incorporates safety features to protect operators and maintain a safe working environment during the plastic kayak making process.

In summary, the HYBM-kayak kayak blow moulding machine stands out as a premier choice for manufacturers focused on producing high-quality plastic kayaks and boats. Its combination of a sizeable 70kg accumulator, easy-to-operate interface, and advanced PLC control system delivers superior performance and reliability. By investing in this plastic kayak making machine, manufacturers can achieve increased productivity, enhanced product consistency, and greater flexibility in their production lines. Whether you are entering the kayak manufacturing industry or looking to upgrade your existing equipment, the HYBM-kayak offers a compelling solution that meets the highest standards of modern plastic kayak production.

Features:

- Product Name: Kayak Molding Machine

- Color: Customized to meet your requirements

- Power Source: Electric

- Model: HYBM-kayak

- Capacity: Designed for plastic kayak and boat production

- Key Selling Points: Easy to operate, ensuring efficient manufacturing

- Specialized kayak blow moulding machine for high-quality kayak production

- Reliable plastic boat machine suitable for various plastic boat designs

- Advanced plastic boat machine technology for durable and precise molding

Technical Parameters:

| Model | HYBM-kayak |

| Power Source | Electric |

| Frequency | 60Hz |

| Key Selling Points | Easy To Operate |

| Capacity | Plastic Kayak/boat |

| Molding Method | Blow Moulding |

| Accumulator | 70kg |

| Warranty | 1 Year |

| Color | Customized |

| Control System | PLC |

Applications:

The huayu HYBM-kayak plastic kayak making machine is an advanced and reliable solution designed specifically for the efficient production of high-quality plastic kayaks. With its robust build and user-friendly operation, this plastic boat machine is ideal for manufacturers seeking to streamline their kayak production processes. Certified with CE, ISO9001, and SGS, the HYBM-kayak model ensures compliance with international quality and safety standards, making it a trusted choice in the industry.

This plastic kayak making machine is perfectly suited for various industrial applications, including specialized kayak manufacturing plants, recreational watercraft factories, and custom plastic boat production facilities. The machine’s easy-to-operate design allows operators with minimal technical background to manage the production line effectively, reducing downtime and improving overall productivity. Its screw diameter of 110mm*2 ensures consistent melting and molding of plastic materials, resulting in durable and well-formed kayak bodies.

Given its frequency of 60Hz and adaptable voltage options tailored to customer needs, the huayu HYBM-kayak plastic boat machine can be seamlessly integrated into diverse manufacturing environments worldwide. Its supply ability of 40 sets per year and a minimum order quantity of just one unit make it accessible for small to large-scale enterprises. Packaging is customized according to customer requirements, ensuring safe delivery within an estimated timeframe of 4-6 months after order confirmation. Payment terms are flexible, supporting TT or L/C, facilitating smooth international transactions.

The huayu HYBM-kayak is especially beneficial in scenarios where precise and consistent production of plastic kayaks is critical, such as seasonal demand surges for water sports equipment, expansion of recreational boat offerings, or replacement of outdated machinery with modern, efficient technology. Whether used in a startup manufacturing setup or an established production line, this plastic kayak making machine offers excellent performance, reliability, and ease of use, making it a valuable asset for any plastic boat manufacturing operation.

Customization:

Our huayu HYBM-kayak blow moulding machine offers exceptional product customization services tailored to your specific needs. As a leading plastic kayak blow moulding machine from China, it is certified with CE, ISO9001, and SGS, ensuring top quality and reliability. With a minimum order quantity of just 1 unit, we provide flexible pricing through negotiation to suit your budget.

The HYBM-kayak model features a PLC control system and utilizes the blow moulding method, ideal for producing high-quality plastic kayaks and boats. Equipped with a 70kg accumulator, this blow moulding machine delivers consistent performance and efficiency. Voltage specifications can be customized according to your requirements.

We offer packaging details customized as per customer needs and guarantee a delivery time of 4-6 months. Payment terms are flexible with options including TT or L/C. With a supply ability of 40 sets per year, we are well-equipped to meet your production demands.

FAQ:

Q1: What is the brand and model number of the Kayak Molding Machine?

A1: The Kayak Molding Machine is manufactured by the brand Huayu, and the model number is HYBM-kayak.

Q2: Where is the Kayak Molding Machine produced?

A2: The Kayak Molding Machine is made in China.

Q3: What certifications does the Kayak Molding Machine have?

A3: The machine holds CE, ISO9001, and SGS certifications, ensuring quality and safety standards.

Q4: What is the minimum order quantity and pricing for the Kayak Molding Machine?

A4: The minimum order quantity is 1 unit, and the price is negotiable based on order details.

Q5: What are the payment terms and delivery time for the Kayak Molding Machine?

A5: Payment can be made via TT (Telegraphic Transfer) or L/C (Letter of Credit). The typical delivery time is between 4 to 6 months.